Polypropylene rope comprises synthetic fibers. They do not contain natural fibers like cotton, hemp, or sisal rope. So, polypropylene is not biodegradable. The synthetic properties of polypropylene rope ensure it lasts longer. These ropes are also stronger and more resistant to water and chemicals. Polypropylene is a relatively new product, having been invented in 1951.

Since polypropylene rope comprises synthetic fibers, take extra care when cutting your rope. You’ll want to follow the proper steps to prevent fraying.

You’ll also want to seal the ends of your rope to prevent fraying. The best ways to seal synthetic ropes are splicing, heat-sealing, or using a hot knife. You can also seal your rope using whipping or end caps. These methods are usually reserved for natural ropes, though.

How strong polypropylene ropes are depends on their diameter and their weaving pattern. Solid-braided and double-braided ropes tend to be the strongest. Twisted ropes are the weakest. You’ll also need to consider the rope’s tensile strength and working load to determine how strong the rope is.

Polypropylene ropes have water-resistant properties. So, they are most often used for boating and marine applications. Still, there are seven other common uses for polypropylene rope:

- Agriculture

- Construction & Engineering

- Military

- Pet Leads

- Water Sports

- Rock Climbing/Mountaineering

- Home Goods & Lawn Decorations

To decide if polypropylene is the right rope for you, consult the charts I’ve constructed below. These charts compare the advantages and disadvantages of polypropylene rope. They also compare polypropylene ropes to other synthetic fiber ropes.

What Are Polypropylene Ropes?

Polypropylene is a synthetic thermoplastic polymer. It is similar to polyethylene but is slightly harder and more resistant to heat. It is also resistant to acids, alkalis, oils, alcohols, and organic solvents.

Polypropylene is the second most produced commodity plastic; polyethylene is the first. Commodity plastics are generally weaker, inexpensive materials that are mass-produced.

Polypropylene rope is also similar to polyester rope but is cheaper. Polypropylene is also resistant to abrasion and very durable. These ropes are flexible and good for tying knots.

These ropes tend to be weaker than nylon and polyester. Still, boaters prefer it for marine applications because of its buoyancy and affordability.

The History Of Polypropylene Rope

J. Paul Hogan and Robert Banks were Phillips Petroleum chemists. In 1951, they unveiled propylene’s creation, or polymerization, for the first time. Their discovery led to the production of polypropylene plastics on a massive scale.

How To Cut Polypropylene Rope

To cut a polypropylene rope properly, you’ll want to cut the rope at a 45 to 55-degree angle. Hold the rope with both hands and begin cutting at the thickest side. Gradually move through the thinner side as you cut. Cutting the rope in this manner keeps the edges sharp. It also gives you the right angle without splitting the fibers.

While cutting your rope, avoid applying too much pressure or tension. You should apply enough pressure to cut through the rope, but don’t overdo it. Cutting the rope too quickly causes split tips. Cutting the rope too slowly will cause overflow. After cutting the rope, you’ll need to seal the ends.

How To Keep Polypropylene Rope From Fraying

To prevent your polypropylene rope from fraying, you’ll need to seal the ends.

There are five effective ways to seal your rope:

- Splicing

- Heat Sealing

- Hot Knife

- Whipping

- End Caps

Splicing

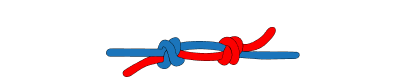

Splicing the rope seals the rope without causing fraying or using knots. You’ll loop the end of the rope back in on itself and weave the fibers of the ends together. You can also do this with two separate ropes to combine the ropes into one. You can either create a soft or hard splice, otherwise known as an “eyelet.”

Heat Sealing

Heat sealing is the easiest way to prevent your ropes from fraying, and it only works on synthetic ropes.

The best way to heat seal a rope is by using a blow torch. A blow torch will heat the fibers evenly, ensuring your rope has a cleaner finish. You can also use a lighter or a candle in place of a blow torch. Bear in mind that a candle will likely leave soot on your rope.

To seal the rope, first hold it in your non-dominant hand, about 5-6 in (12.7-15.2 cm) from the flame. Second, lower the rope close to the flame until it begins melting. Keep melting the fibers until the end of the rope is completely sealed.

Hot Knife

Using a hot knife is another way to seal your rope. Like heat sealing, you can only use hot knives on synthetic ropes.

First, place the rope against a thick piece of glass or flame-resistant tile. Second, plug in your heat knife and press it gently against the fibers. You’ll want to place the knife on the threads about 1 in (2.54 cm) from the rope’s end. Third, move the blade back and forth against the rope’s end. The knife will begin melting the fibers and sealing the rope’s end.

Whipping

To whip the end of your rope, you’ll tie twine around the ends of the rope. Whipping prevents your rope from fraying and provides an appealing finish. The whipping method is usually reserved for natural ropes. There are easier methods for sealing synthetic ropes. Still, you can whip your synthetic polypropylene rope if you have the materials on hand.

Use End Caps

End caps are also primarily used for natural fiber ropes, but you can apply them to synthetic ones, too. End caps are similar to whipping but are stronger and more durable. End caps are usually preferable for more heavy-duty uses. A rigid plastic cap is sealed onto the ends of the rope with heat to prevent the fibers from unraveling.

Polypropylene Rope Strength

Polypropylene rope is weaker than other synthetic ropes like nylon and polyester. Still, it is stronger than natural ropes like hemp and jute. Firstly, the strength of polypropylene rope depends on the diameter of the rope. Thicker ropes are stronger than thinner ropes. Secondly, the strength depends on the weaving of the rope. Braided ropes tend to be stronger than twisted ropes.

Solid Braided Ropes

Solid braided ropes consist of 16 or more strands woven together to create a compact rope. Strands can have different diameters, up to 2 in (5 cm), so you can get ropes of varying thicknesses and strengths.

The surface of solid braided polypropylene ropes comprises a twill pattern. Twill patterns are woven in diagonal, parallel ridges. The twill pattern makes creating ropes of varying colors and patterns easy.

Solid braided rope is easier on the hands and almost always stronger than twisted rope. It’s more flexible and less stiff than twisted rope. Still, braided rope is more difficult to splice and is less elastic than twisted rope.

Some may contain a core inside the rope, while others don’t. Solid braids want to stay round in shape so you can use them in more applications.

Diamond Braided Ropes

Diamond braids consist of a diamond pattern on the outside of the rope. These ropes tend to be easier on your hands, easier to grip, and lighter to work with. Like solid braids, some diamond braids may have a core.

Hollow Braided Ropes

Hollow braids are woven together to create a tight tube with a hollow center. Since the center of these ropes are hollow, they are often weaker than solid and diamond braids.

Double-Braided Ropes

A double braid has a braided core covered with a braided jacket. These types of ropes tend to be stronger than all the other braids.

Twisted Ropes

Twisted rope is created by laying long fibers on top of each other. Then, the fibers are rolled or twisted into a spiral pattern.

Twisted ropes are usually more difficult to grip and harder on the hands. They are more elastic than braided rope, are easier to splice, and are more affordable. Twisted ropes tend to be stiffer and more likely to kink.

Tensile Strength VS Working Load

The tensile strength refers to the maximum load a rope can carry without breaking. It measures the total force needed to break a rope under controlled conditions. Tensile strength is determined within a factory setting. It does not accurately portray the safe amount of weight a rope can actually hold.

The working load takes into account that the rope is going to be used by workers. It considers wear-and-tear that the rope will experience. For instance, working load considers possible abrasion, temperatures, chemicals, and knots. It recognizes that these factors will considerably lessen the strength of the rope.

The working load gives us the absolute maximum load we should place on a rope. Most experts recommend working well below the working load to be safe.

Consult this chart to see an example of tensile strength and working load for twisted rope:

Tensile Strength Of Twisted Polypropylene Ropes By Diameter

| Diameter | Tensile Strength | Working Load |

| 6 mm | 1,250 lbs | 212 lbs |

| 10 mm | 2,700 lbs | 459 lbs |

| 16 mm | 6,200 lbs | 1,054 lbs |

| 22 mm | 11,500 lbs | 1,955 lbs |

| 32 mm | 21,000 lbs | 3,570 lbs |

| 38 mm | 29,700 lbs | 5,049 lbs |

| 45 mm | 43,000 lbs | 7,310 lbs |

| 57 mm | 69,000 lbs | 11,730 lbs |

| 64 mm | 80,000 lbs | 13,600 lbs |

| 76 mm | 114,000 lbs | 19,380 lbs |

What Is Polypropylene Rope Used For?

Polypropylene rope has eight general uses:

- Agriculture

- Fisheries & Boating

- Construction & Engineering

- Military

- Pet Leads

- Water Sports

- Climbing

- Home Goods & Yard Decorations

Consult this chart for common polypropylene rope uses based on diameter:

Uses For Polypropylene Rope Of Varying Diameters

| 6 mm | Knotting Handymen Gardeners Leashes for small and medium-sized dog breeds |

| 8 mm | |

| 10 mm | Leashes and harnesses for large dog breeds |

| 12 mm | |

| 14 mm | Climbing Nets Mooring & anchoring ropes for small boats/yachts Horse leads |

| 16 mm |

Agriculture

Polypropylene is widely used in the agricultural field. It is useful in farms because it’s light, affordable, and rot, abrasion, and water resistant. The agriculture and fishing industries use more polypropylene rope than any other industry.

These ropes are also suitable for farm and gardening use for supporting crops. Many crops grow tall but are unable to support themselves. It is a good replacement for natural ropes since it is rot-proof and water-resistant. Unlike natural rope, you can reuse polypropylene season after season. Many farmers also use polypropylene rope to pack and ship their crops.

Fisheries & Boating

Like agriculture, polypropylene is extremely common in marine and fishery applications. The ropes are often used for:

- Anchor lines

- Winches

- Life ropes

- Fish nets

These ropes resist tangling, so they won’t get caught in a boat’s propellers or motor. Because it’s resistant to water and rot, it maintains its quality and can be used for a long time.

Fishermen often use polypropylene ropes for the construction of knitted fishing nets. The material is lightweight, does not absorb water, and floats, making it ideal for use as a “float rope.”

These ropes are robust; great for towing and mooring ships into a shipbuilding yard or port.

The synthetic fibers are easily colored, so the ropes come in many vibrant hues. Having colored rope on a boat is helpful, especially when working at night or when the rope must go in the dark water.

Construction & Engineering

Polypropylene rope is standard for construction and engineering. Workers use it to create large nets. The nets must be strong enough to carry heavy construction material between worksites. Workers also use it for pulleys within a worksite. They even add polypropylene rope to the soil of construction sites. Doing so increases the foundation’s strength.

Military

The military often relies on polypropylene rope to tow gunnery targets and rappelling. They also use the ropes for their training courses, using them for climbing ropes and safety nets.

Pet Leads

Polypropylene rope is rot-resistant and does not absorb water. So, it’s not affected by animal sweat.

Water Sports

Lightweight, rot-resistant polypropylene rope is excellent for water sports. These ropes also float, making them ideal for swimming pool dividers. They remain soft, even when wet, so they are easy on the hands. Those that enjoy wakeboarding and waterskiing also find polypropylene ropes helpful.

Rock Climbing & Mountaineering

These ropes’ water, rot, and abrasion-resistant nature make them ideal for climbers. Climbers can feel safe using these ropes for rappelling. More often, climbers use nylon ropes for climbing. Still, polypropylene ropes are good when they need rope with less elasticity.

Home Goods & Yard Decorations

- Carpets/rugs/mats

- Outdoor decorations

- Chairs

- Treehouses

- Railings

Advantages And Disadvantages Of Polypropylene Rope

Easily consider the pros and cons of using polypropylene rope by consulting this chart:

The Pros & Cons Of Using Polypropylene Rope

| PROS | CONS |

| Dielectric Floats Water resistant Chemical resistant Lightweight Affordable Color variety | Elastic Susceptible to abrasion Susceptible to high temperatures Highly flammable Not resistant to chlorine Susceptible to UV rays |

How Does Polypropylene Rope Compare To Other Synthetic Ropes?

Consult this chart to compare the qualities of polypropylene rope to other synthetic ropes:

Comparison Of Synthetic Ropes

| Polyamide (Nylon) | Polyester | Polyethylene | Polypropylene | |

| Abrasion Resistance | Great | Great | Fair | Fair |

| Acid Resistance | Good | Great | Great | Great |

| Alkali Resistance | Great | Great | Great | Great |

| Buoyancy | Sinks | Sinks | Slightly Floats | Floats |

| Durability | Great | Great | Fair | Good |

| Handling | Great | Great | Good | Good |

| Strength | Great | Good | Good | Fair |

| Melting Point | About 250°C (484°F) | About 245°C (473°F) | About 128°C (262°F) | About 150°C (302°F) |

| Rot & Mildew Resistance | Great | Great | Great | Great |

| Shock Loading | Great | Fair | Poor | Good |

| Storage | Wet or Dry | Wet or Dry | Wet or Dry | Wet or Dry |

| U.V. Resistance | Fair | Great | Fair | Poor |

FAQs

Is Polypropylene Rope Safe For Pets?

Polypropylene rope is frequently used for leads and harnesses for pets. In this regard, polypropylene is entirely safe. It is one of the best materials for leads since it’s weather-resistant.

Most veterinarians agree that you shouldn’t offer your pet polypropylene rope toys. When your pet chews on the rope, they will likely break down the fibers and swallow them. Rope fibers can get stuck in the digestive tract and become life-threatening. Ingested rope fibers are more dangerous for your pet than chunks of plastic or rubber.

Can You Dye Polypropylene Rope?

The composition of polypropylene rope makes it impossible to dye. Still, you can buy pre-colored polypropylene rope. Polypropylene is colored with pigment while still in its liquid form. Then, the liquid is extruded into a fiber that retains the coloration. Polypropylene ropes are highly regarded for the variety of colors they come in. The colors often make them easier to work with, especially in dark environments.